Phase II PTG-5500

Coating thickness testing performance is both non-destructive and extremely accurate.

Features

- Two measuring modes

- Automatic temperature compensation

- Displays five statistical values

- Simple 1-step calibration using supplied metal plate and reference shims

- Close to 500 measurements in memory (99 measurements/group x 5 groups)

- Alarm when measurements out of tolerance

- Displays remaining power in battery

Applications

- Coating thickness measurement

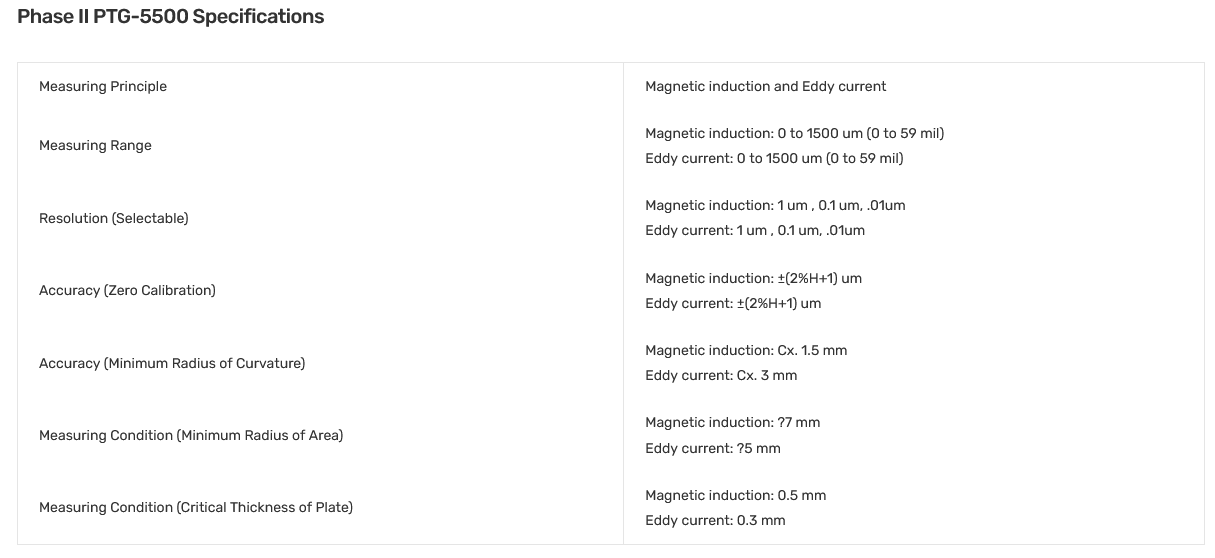

The PHASE II PTG5500 Coating Thickness Gage with Auto-Detect Probe can perform two different methods of calculating coating thickness measurement by utilizing the characteristics of both eddy current and magnetic induction.

Coating thickness testing performance is both non-destructive and extremely accurate.

With the PTG-5500 state-of-the-art coating thickness gauge, users can easily detect the thickness of nonmagnetic coating on a magnetic substrate (ferrous), or an insulating coating on a non-magnetic conductive substrate (non-ferrous), utilizing the included auto-detect probe

The PTG-5500 coating thickness gauge can be used in many areas of industry, including automotive auctions, manufacturing, general engineering, commercial inspection, etc.

The PTG-5500 coating thickness gauge utilizes a rugged probe that can automatically detect a Ferrous or Non-Ferrous substrate and comes with 2 substrate samples (steel, aluminum), 4 calibrated thickness samples, carrying case, batteries, and an operation manual.

with the Phase II PTG-5500

- Coating Thickness Gauge

- Steel Substrate Sample

- Aluminum Substrate Sample

- 4 x Calibrated Thickness Sample

- Cable

- Carrying Case

- Batteries

- Data Output Software

- Operation Manual