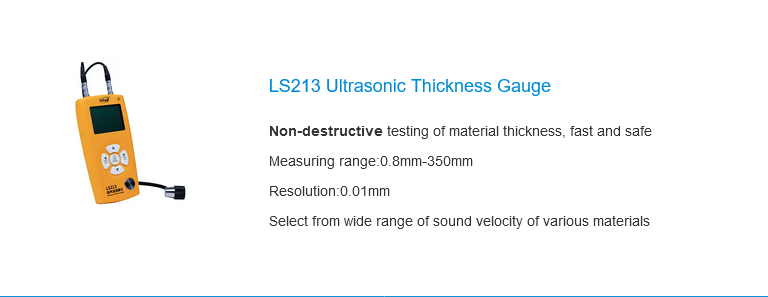

LS213 Ultrasonic Thickness Gauge

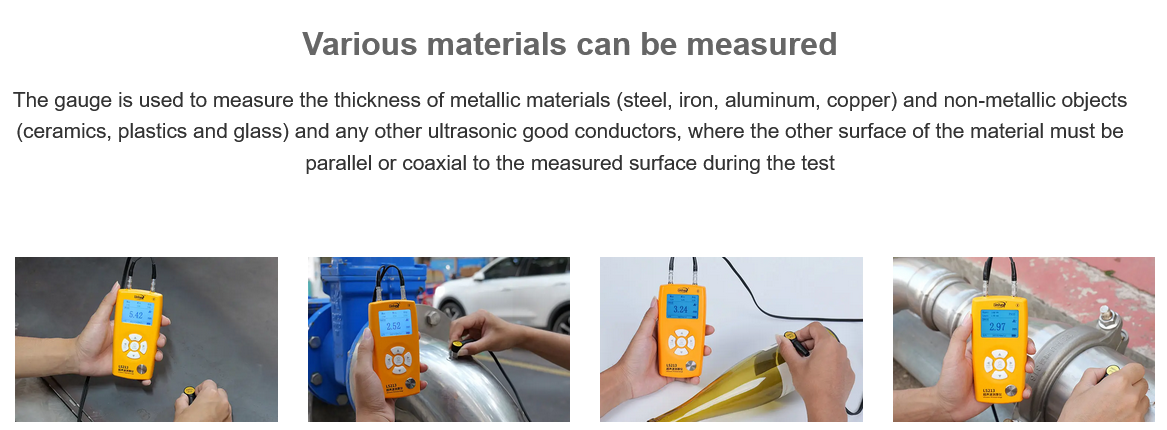

Non-destructive for metal, glass, ceramics and plastics

Precision ultrasonic thickness gauge provide fast, accurate readings

Two measurement modes: QC Mode/Statistics Mode

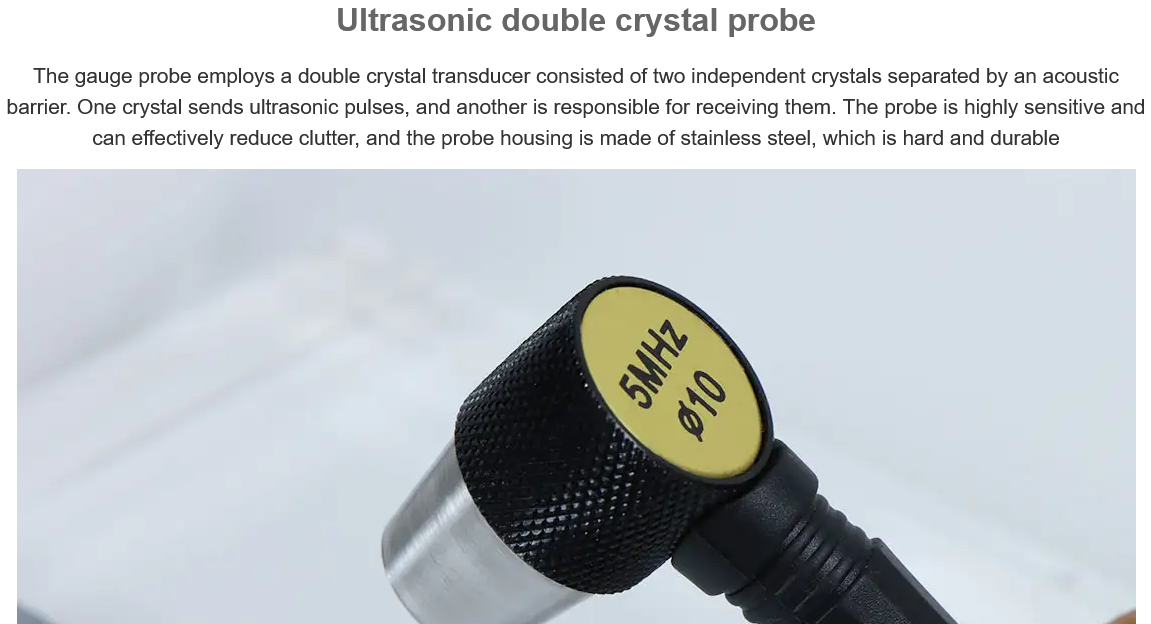

High-sensitive dual-crystal probe

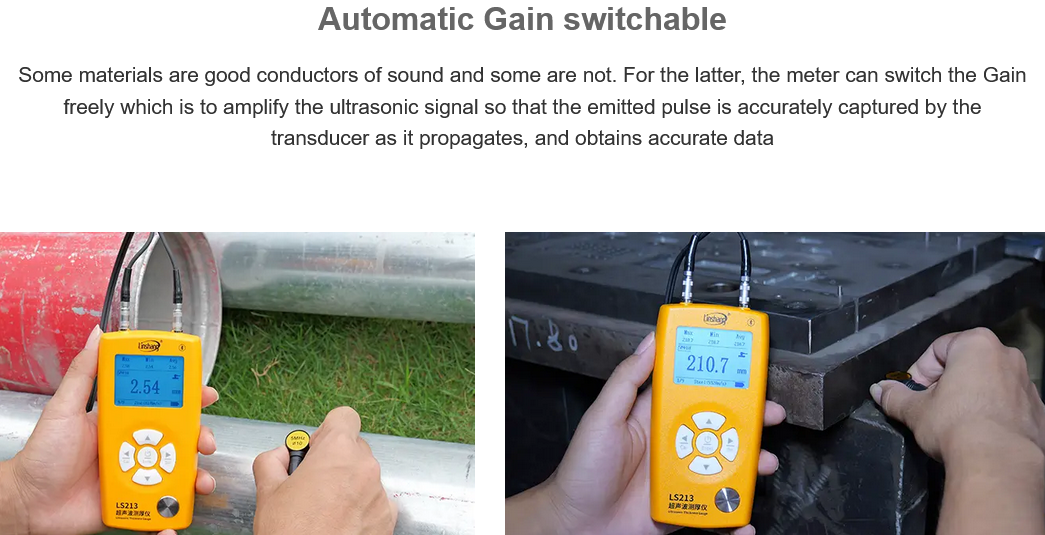

Automatic Gain switchable

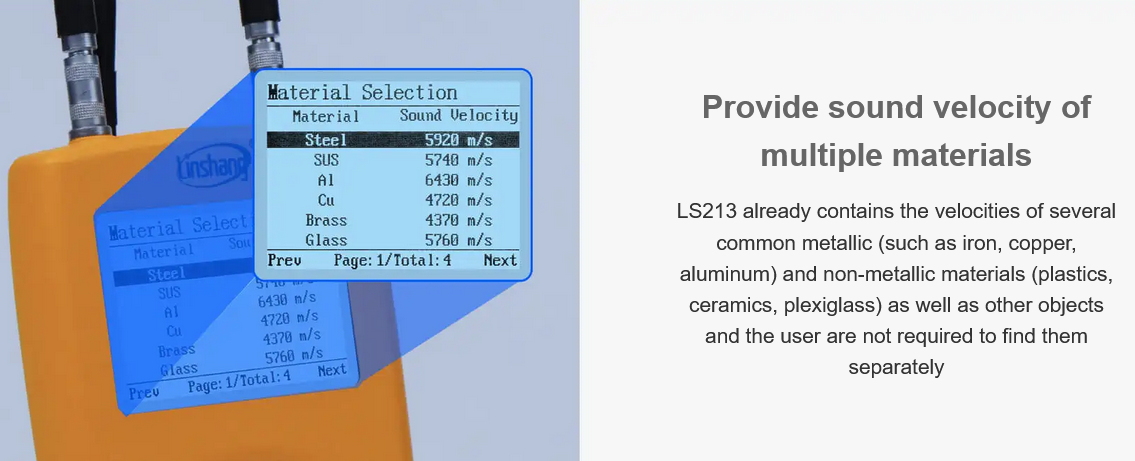

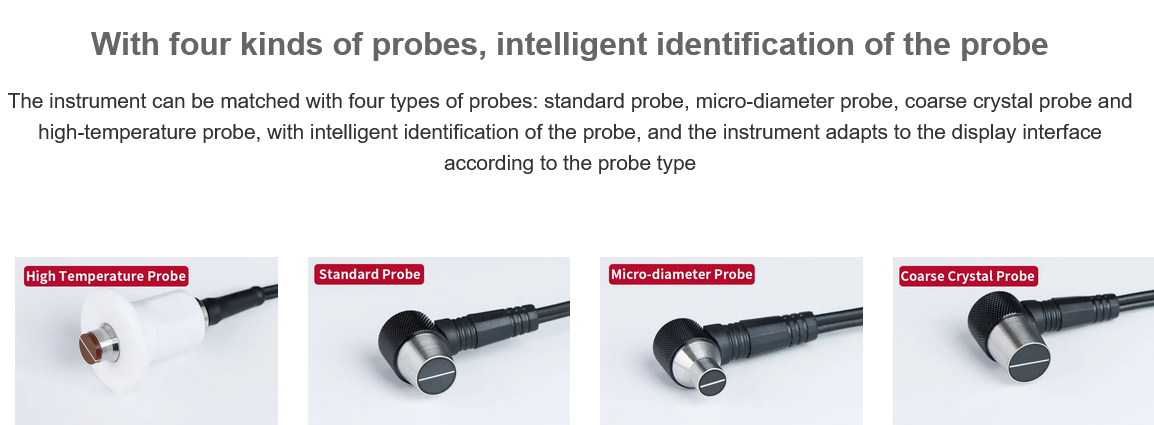

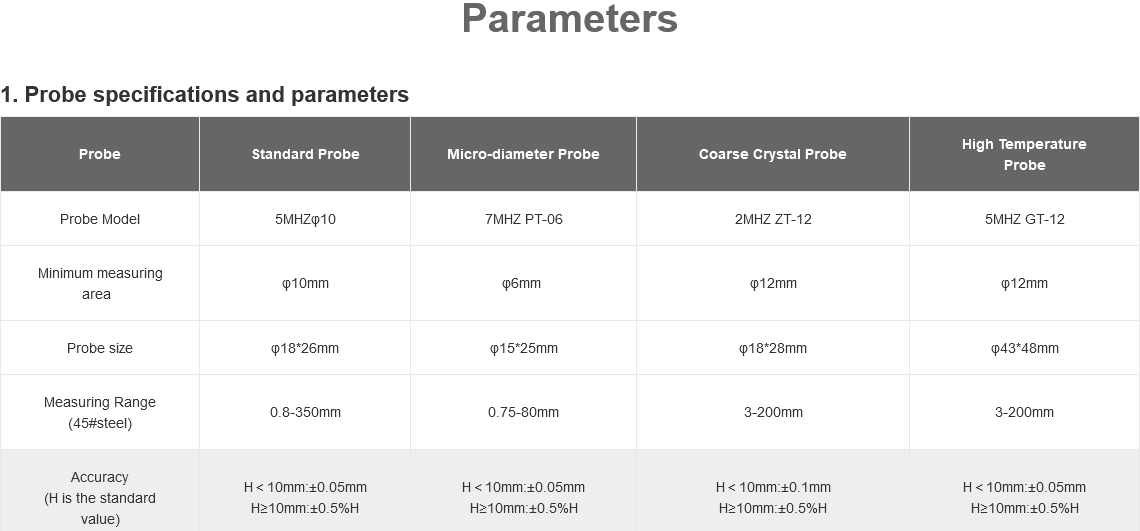

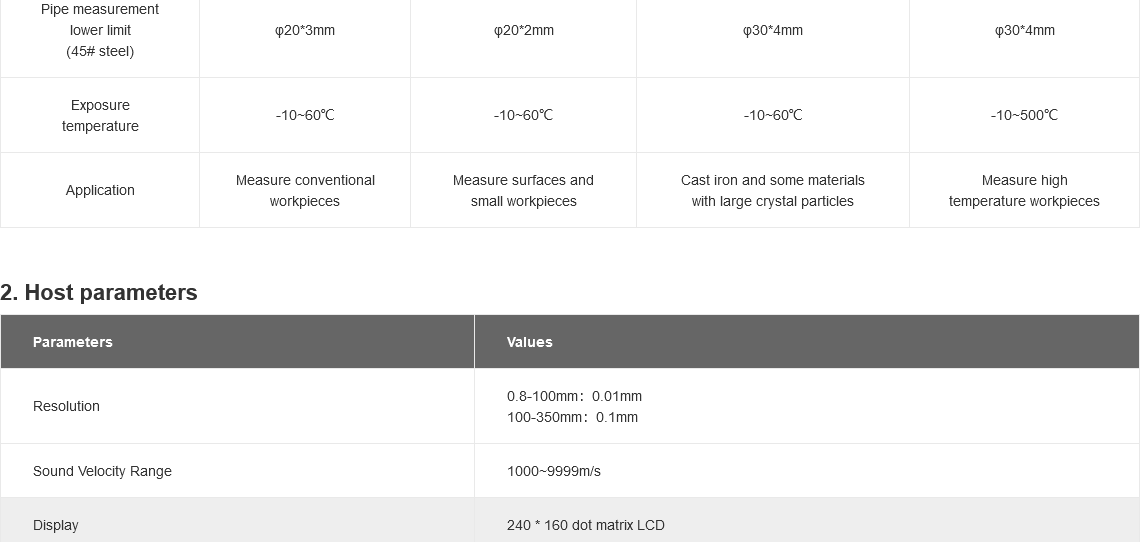

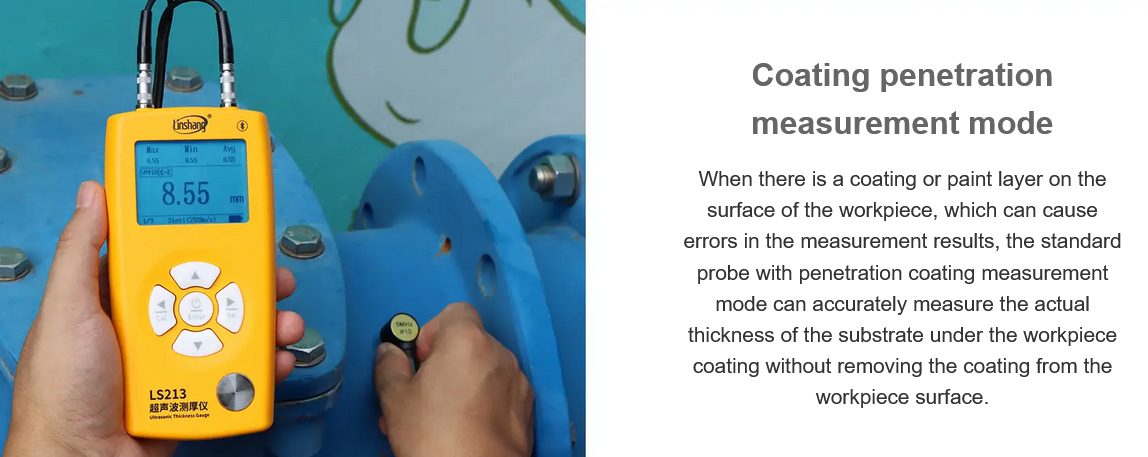

LS213 ultrasonic thickness gauge is easy to operate and uses the principle of ultrasonic pulse reflection to test the thickness of materials. The instrument can be equipped with four types of probes: standard probe, micro-diameter probe, coarse crystal probe and high-temperature probe, and is professionally used for thickness measurement of metals (such as steel, aluminum, copper, etc.), plastics, ceramics, glass, fiberglass and other materials that can transmit ultrasonic waves. The instrument adopts professional timing chip design, the resolution is up to 0.01mm

Application

In many industries, It is essential to measure the wall thickness to confirm the condition of the material for the normal running of the items or structure safety. LS213 ultrasonic thickness gauge can be widely used in testing the thickness of various accessories or metallic structure to check them whether to be repaired or changed such as ships, tanks, pipes or steel structure. The gauge is applicable for petroleum, chemical, metallurgical, shipbuilding, aviation and aerospace various fields.

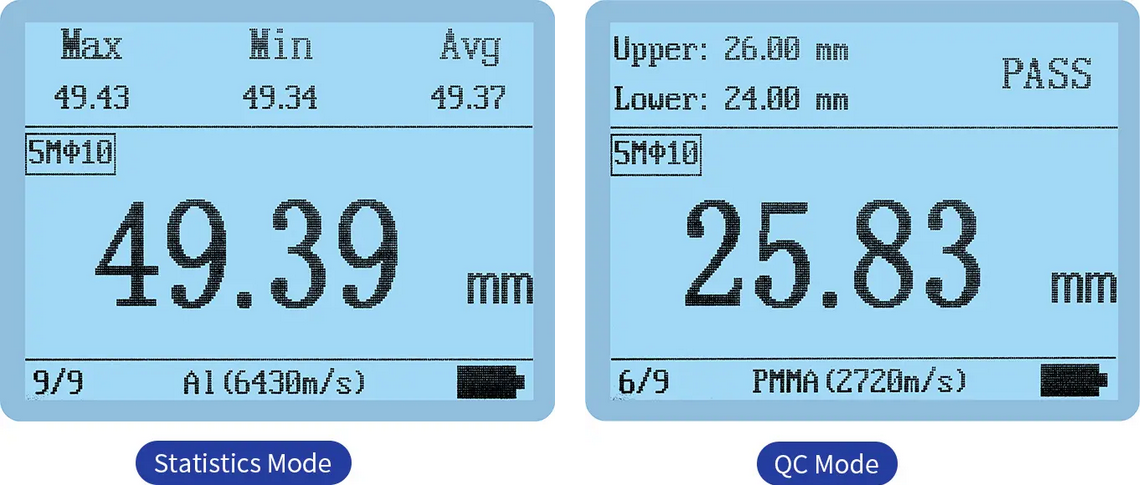

QC Mode and Statistics Mode

LS213 ultrasonic thickness gage sets up two measurement mode: QC mode and statistics mode. The former is allowed to set upper and lower limits to check the problem areas by prompting NG or PASS. It will count maximum, minimum and average values of data in statistics mode